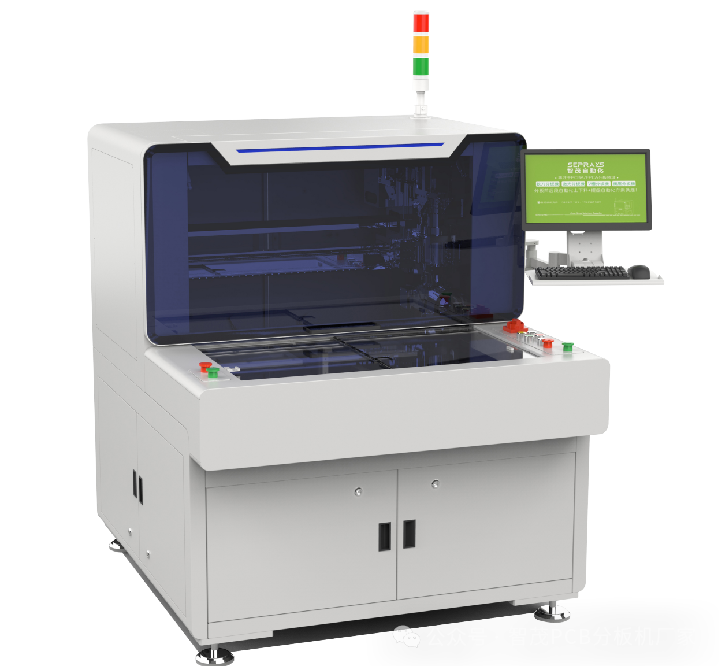

ZM300N Vision-Based PCB Depaneling Router: High Efficiency & Precision for Automated Board Separation.

The ZM300N is a vision-based milling router engineered to meet the demands of automated PCB depaneling. Combining advanced industrial vision recognition with a user-friendly operating experience, it delivers high cutting efficiency and simplified vision-assisted programming. Its dual workstations allow for simultaneous depaneling and manual board handling, significantly reducing wait times and enhancing productivity. The ZM300N is widely used across industries such as aerospace, communications electronics, semiconductors, medical electronics, and automotive electronics for panelized and multi-panel PCB boards.

I. Four Key Advantages

1. High Efficiency

Equipped with an imported spindle that reduces stress during routing, the ZM300N ensures stable performance while improving efficiency. It increases production capacity by 30% compared to similar models.

2. High Precision

With automatic calibration and a high-resolution CCD camera that magnifies images 15 times, the ZM300N enhances programming and positioning accuracy, guaranteeing superior cutting precision. It supports MARK point setup and full-board scanning.

3. Clean and Visible Operation

Compatible with both upper and lower dust collection systems, the ZM300N ensures effective dust capture for a truly clean and dust-free working environment.

4. Dual Workstations

The dual workstation design enables simultaneous depaneling and manual board loading, minimizing downtime and boosting overall production efficiency.

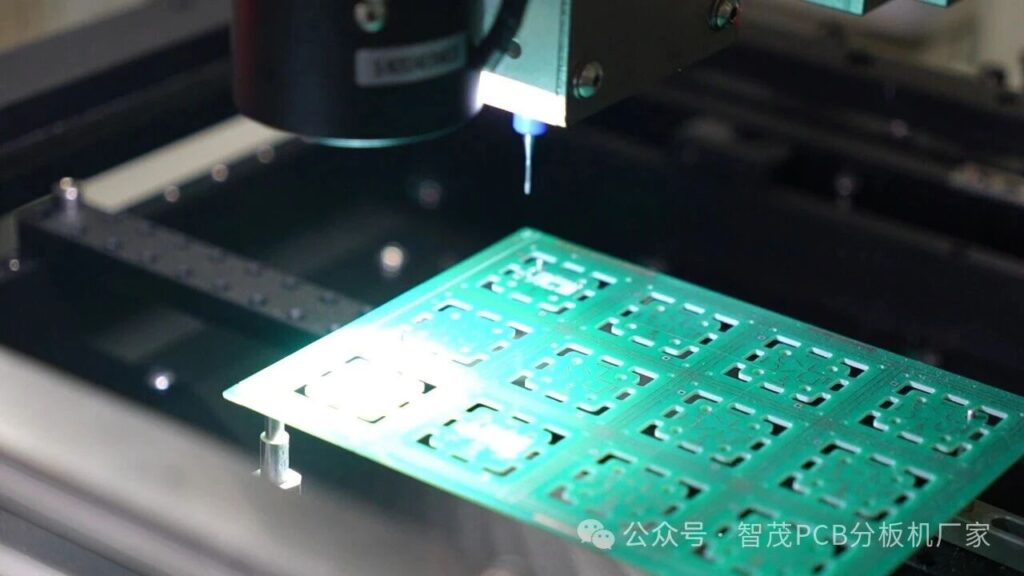

II. ZM300N Application Scenarios

The ZM300N effortlessly handles complex cutting tasks—including straight lines, L-shapes, U-shapes, circles, and arcs. It is ideal for high-precision products in automotive electronics, medical devices, and military applications, delivering an hourly output that is 30% higher than competing solutions.

2.1 German-Imported Spindle

The high-precision spindle reaches a maximum speed of 80,000 RPM and includes features such as milling cutter life management, maintenance alerts, and configurable spindle speed settings.

2.2 Precision Board Separation Structure

The Z-axis integrates a high-definition CCD module with built-in dust extraction. Using a high-speed ESD automatic tool-changing spindle, it effectively dissipates static electricity generated during separation, minimizing the risk of electrostatic damage to PCBA.

2.3 Dual Dust Extraction Modes

Operators can choose between top or bottom dust extraction modes, offering flexibility to adapt to a wide range of product requirements.