Product Details

Application

Application:LCP、MPI、PI、PET、FR4、FR5, CEM, polyester materials, ceramic materials and other radio frequency materials.

Application Field:Semiconductors, integrated circuits, communications, lighting, etc.

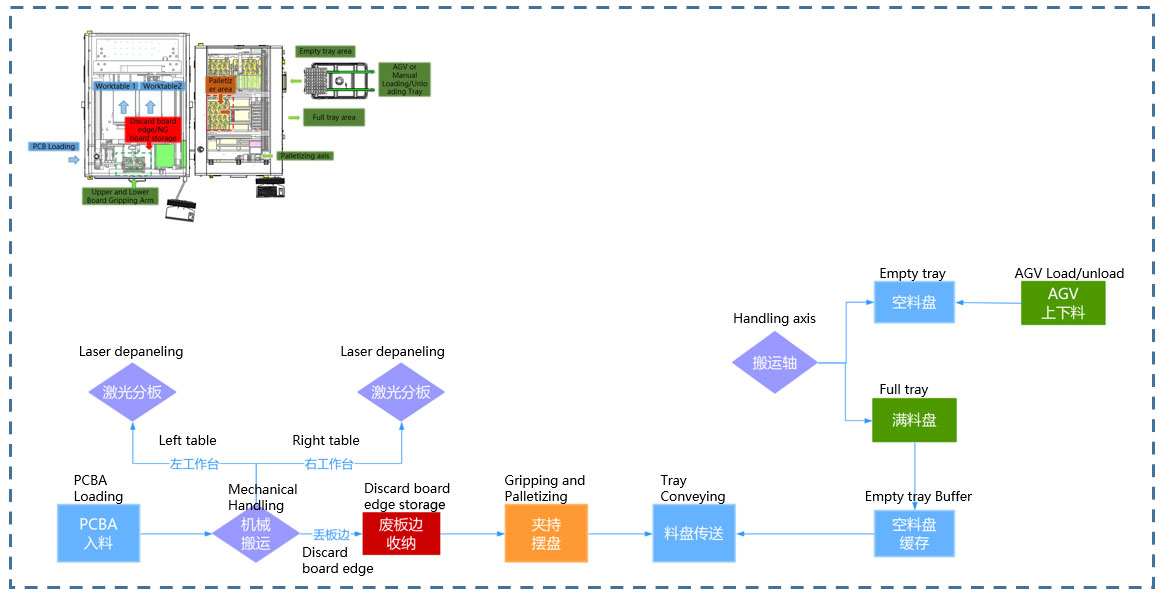

Workflow

Automated System

Facing mass production and industrial applications, entering a new era of manufacturing

SEPRAYS/GENITEC laser depaneling equipment can choose different types of loading and unloading systems, and set up a standard industrial interface, which can be integrated into the MES system to support the collection, distribution, production tracking. Can provide customzied service.

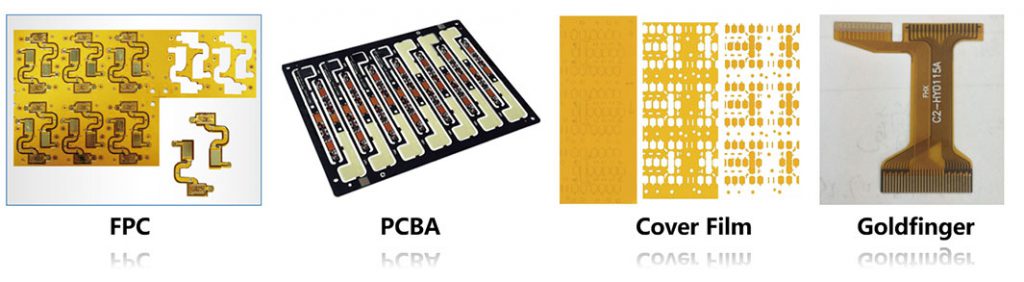

Cutting Cases

LCP、MPI、PI、PET、FR4、FR5, CEM, polyester materials, ceramic materials and other radio frequency materials.

Parameter

-

ModelZAM330AT

-

Data Processing SoftwareCircuitCAM 7

-

Operating SoftwareDreamCeaTor 3

-

Laser SourceOption UV/Green Light/Infrared, Picosecond/Nanosecond

-

Max. Processing Area300mmx300mm (Dual Work tables)

-

Scanning GalvointelliSCAN+RTC5

-

Telecentric LensWavelength-related

-

ReflectorWavelength and Power-related

-

MotorServo Motor

-

Motion Control CardGTS-400

-

CCD Light SourceAnnular Light

-

Industrial PCCPU: I5, Memory: 4GB/DDR3, Hard Drive: 1TB

-

Monitor17-inch LCD Screen

-

Platform StructureMarble

-

Appearance Dimensions1620mm*1770mm*2250mm

What services do you provide?

What services do you provide?

We provide one-stop automated PCB depaneling solutions: laser, routing, punching and V-CUT.

Can your machines handle different thicknesses of PCBs?

Yes, our machines are designed to handle various PCB thicknesses. We can provide customization and options to ensure smooth processing of both rigid and flex boards.

What type of training do you provide for your machines?

We provide comprehensive on-site training, covering machine operation, maintenance, and troubleshooting. We also offer ongoing technical support via phone and email.

What after-sales services can you provide?

●Exclusive service:

We will give users feedback within 10 minutes on any problems they encounter when using the device and establish a 1V1 exclusive after-sales service group for users.

●Remote service:

Provide users with a 7*24H hotline based on feedback on fault information, analyze, locate, and solve the fault through remote telephone support,remote login, and other methods.

●On-site service:

Arrive at the work site within 8 hours and solve the problem within 1 working day. 2-4 days of training on equipment safety operation and application.Any breach of contract will be handled by the contract provisions.

●Service locations:

We have sales and service support in 31 countries and regions overseas, responding to customers’ current and future needs as soon as possible.

●Benchmark service:

Follow-up call after each visit; video tutorials + telephone guidance on parts replacement and equipment maintenance; free follow-up month in December every year. We continue to collect user suggestions, continuously update and iterate the software, improve user production quality and efficiency, and provide lifelong maintenance.