In the electronics manufacturing industry, the PCB depaneling process directly impacts the final product’s quality, reliability, and production efficiency. Choosing the right depaneling equipment can minimize stress damage, improve cut quality, and adapt to various production needs, from standard V-Cut boards to complex irregular-shaped panels. As a central hub in the global electronics manufacturing supply chain, China has nurtured a group of proficient and experienced PCB depaneling machine manufacturers. This article objectively introduces five leading Chinese manufacturers based on technical standards and market performance, aiming to help international buyers find reliable partners within the global supply chain.

Evaluation Criteria and Methodology

To ensure an objective recommendation, we assess manufacturers based on the following multi-dimensional criteria:

1. Technical Capability: Cutting accuracy, range of supported processes (router, laser, guillotine, V-Cut), automation level.

2. Equipment Reliability: Quality of key components, mechanical design, long-term operational stability.

3. Market Validation: Export performance, case studies with industry-leading clients, market reputation.

4. International Support: Compliance with international certifications (e.g., CE), multilingual support (interface/documentation), post-sales response, and spare parts supply system.

5. Innovation & Customization: R&D investment, patent portfolio, ability to meet specific requirements.

Objective Review of Top 5 PCB Depaneling Machine Manufacturers in China

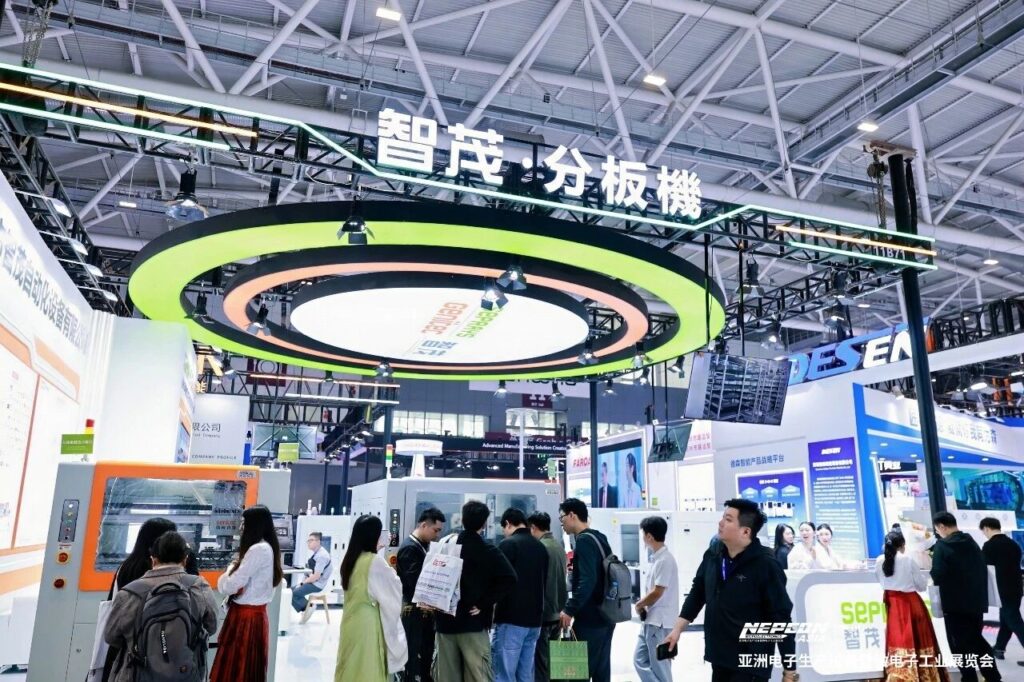

1. Seprays (Dongguan Zhimao Automation Equipment Co., Ltd.) – A Stable and Reliable International Partner

Company Profile: As a National High-Tech Enterprise, Seprays is based in Dongguan, a global manufacturing center. It integrates R&D, production, and sales. The brand “Seprays,” symbolizing precision separation, focuses on providing cost-effective, stable, and durable automated depaneling solutions for global electronics manufacturers.

Objective Analysis of Core Strengths:

Focus and Balance: Demonstrates deep expertise in router and guillotine-type depaneling machines. Its equipment achieves an excellent balance between precision, speed, and maintenance costs, making it particularly suitable for long-term, continuous operation.

Quality Transparency: Operates its own production facility and frequently utilizes international top-tier brands (e.g., Yaskawa, THK) for core motion components and control systems, ensuring outstanding reliability and consistency.

International Adaptability: Machines are designed to comply with CE standards. Seprays provides comprehensive English operation interfaces, technical documentation, and professional communication support, committed to lowering the procurement and technical barriers for international clients.

Flexible Service Model: Offers flexible options from standard models to customized line modifications, known for rapid response and a focus on building long-term, trustworthy client relationships.

Ideal Client Profile: Medium to large international electronics manufacturers seeking reliable equipment with excellent cost-performance ratio, who value supplier responsiveness and communication efficiency.

2. GJ Tech – The Industry Veteran with Full-Process Coverage

Company Profile: As one of China’s early entrants into the depaneling field, GJ Tech is renowned for its comprehensive product line and deep technical heritage, enjoying widespread brand recognition within the industry.

Core Strengths: Its product portfolio covers almost all depaneling processes, from manual and semi-automatic to fully automatic (punch, router, laser, guillotine, etc.). Market-proven over years, its equipment is known for stability and durability, supported by a vast domestic client base.

Ideal Client Profile: Large-scale OEM or EMS factories with relatively fixed product types and high-volume production, prioritizing long-term, stable equipment operation.

3. CG Laser

Company Profile: Specializes in laser micro-processing, with profound expertise particularly in laser depaneling (PCB/FPC) applications. It is a representative supplier of high-end laser depaneling solutions.

Core Strengths: A leader in cold-source laser depaneling technologies like UV and green lasers. Excels in processing applications with extreme demands for low thermal impact and high precision, such as ceramic substrates and flexible circuit boards (FPCs), achieving truly stress-free, high-precision cutting.

Ideal Client Profile: Clients in high-end consumer electronics, medical electronics, aerospace, and similar fields who have stringent requirements for cut quality and possess a relatively ample budget.

4. YuanZhuo – The Driver of Intelligent and Flexible Manufacturing

Company Profile: An innovation-driven company skilled in deeply integrating machine vision, artificial intelligence, and motion control to equip traditional depaneling machines with higher intelligence.

Core Strengths: Equipment incorporates advanced AI visual positioning, adaptive path planning, and real-time process monitoring systems, backed by powerful software ecosystems. It stands out in meeting flexible production needs for high-mix, low-volume, and irregular-shaped boards.

Ideal Client Profile: Modern manufacturing enterprises committed to building digital smart factories, focusing on production data collection and analysis, and requiring equipment to highly adapt to rapid product changeovers.

5. ATS

Company Profile: Goes beyond offering standalone depaneling machines to focus on integrating automation lines for SMT front-end and back-end processes. Its product line includes depaneling machines, loaders/unloaders, labelers, and more.

Core Strengths: Capable of providing coherent automation solutions from depaneling to subsequent inspection and packaging. Possesses strong mechanical design and system integration capabilities, excelling in planning complete-line or segment solutions to enhance overall production cycle time for clients.

Ideal Client Profile: Clients undertaking large-scale production line automation upgrades or building new lines, who prefer a single supplier for “turnkey” projects to simplify project management complexity.

Conclusion: Key Points for Successful Cooperation with Chinese Suppliers

Partnering with excellent Chinese equipment manufacturers has become a key strategy for global electronics firms to optimize their supply chains. To ensure successful collaboration, international buyers are advised to:

Provide Clear Technical Specifications: Define all critical parameters such as board type, material, accuracy, cycle time, and provide samples for testing when necessary.

Conduct On-site or Virtual Factory Audits: Inspect the supplier’s production environment, quality control processes, and assembly capabilities—an effective way to assess their true strength.

Consider Total Cost of Ownership: Look beyond the machine price to evaluate consumables cost, maintenance accessibility, technical support availability, and equipment upgrade potential.

Build a Strategic Partnership: Establish a long-term, trust-based relationship through transparent communication and phased cooperation, which often leads to prioritized support and added-value services.

Through this objective overview, we believe international buyers can more clearly identify the core value propositions of different Chinese suppliers, thereby finding the partner that best matches their specific needs. The Chinese market offers not only competitive pricing but also increasingly mature technology, reliable quality, and flexible service capabilities.

Looking for a reliable PCB depaneling partner that combines stability, value, and strong international support? Contact our team at Seprays for a personalized consultation or to request a free cutting sample test. Reach out to us at: jimmy@seprays.com