Seprays’ automated PCB depaneling solutions are now operational in production lines across over 40 countries, providing core equipment support for global manufacturers like Foxconn, Bosch, and CRRC. Through three decades of continuous innovation, this Chinese manufacturer has become a reliable partner in the PCB depaneling field.

Market Trend: Surging Demand for High-End PCB Depaneling

Global electronics are rapidly evolving towards higher density, miniaturization, and complexity, posing unprecedented challenges to PCB depaneling technology. Traditional manual or semi-automatic methods can no longer meet the stringent modern manufacturing demands for precision, efficiency, and consistency.

Industry analysis indicates the global PCB depaneling machine market is projected to reach significant new heights in 2025, with demand for fully automatic, high-precision equipment growing most prominently. Sectors like automotive electronics, aerospace, high-end consumer electronics, and medical devices, which have exceptionally strict quality requirements, are becoming primary markets for advanced depaneling equipment.

Manufacturers now face multiple challenges: how to minimize stress damage during depaneling, improve cutting precision and consistency, achieve seamless integration with automated production lines, and reduce total operational costs.

Why Choose Seprays: Three Decades of Specialization in PCB Depaneling

Corporate Strength & Global Presence

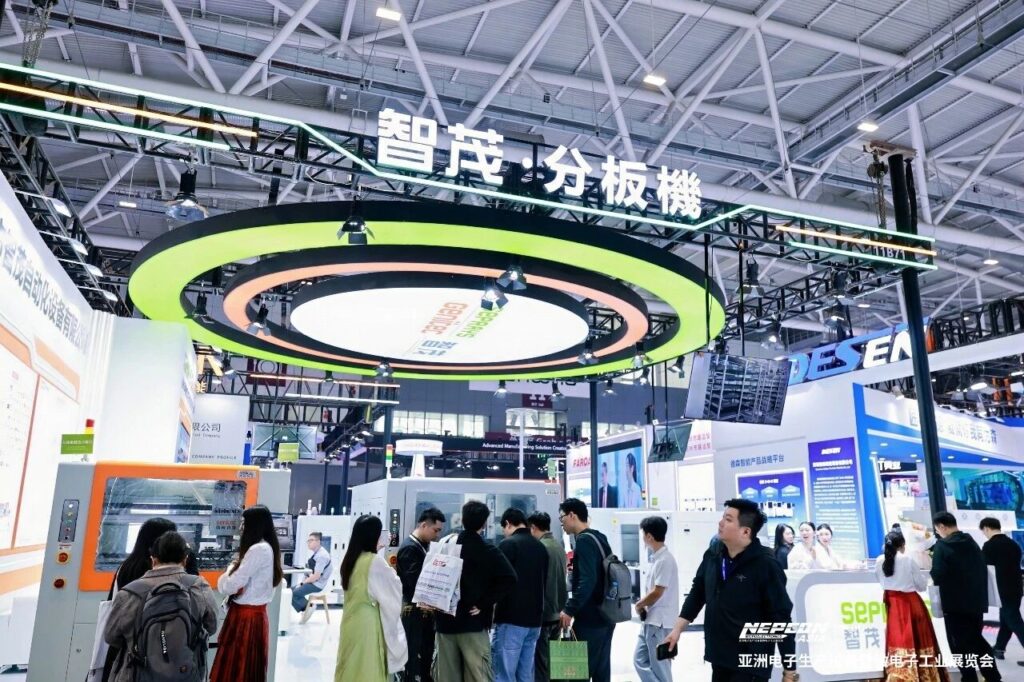

Dongguan Genitec Automation Equipment Co., Ltd. (International brand: Seprays) has been dedicated to the PCB depaneling field for over 30 years since establishing its R&D center in Taiwan in 1993. The company operates a modern production base in Dongguan, China, spanning over 26,000 square meters, forming a complete system integrating R&D, production, sales, and service.

Seprays’ globalized layout enables timely support for customers worldwide. The company has established sales and service networks in 31 countries and maintains local service points in 9 major industrial cities across China. This structure ensures customers receive fast-response technical support and service, regardless of location.

Comprehensive & Innovative Product Line

Seprays offers one of the industry’s most complete PCB depaneling solution portfolios, catering to diverse needs from basic to advanced:

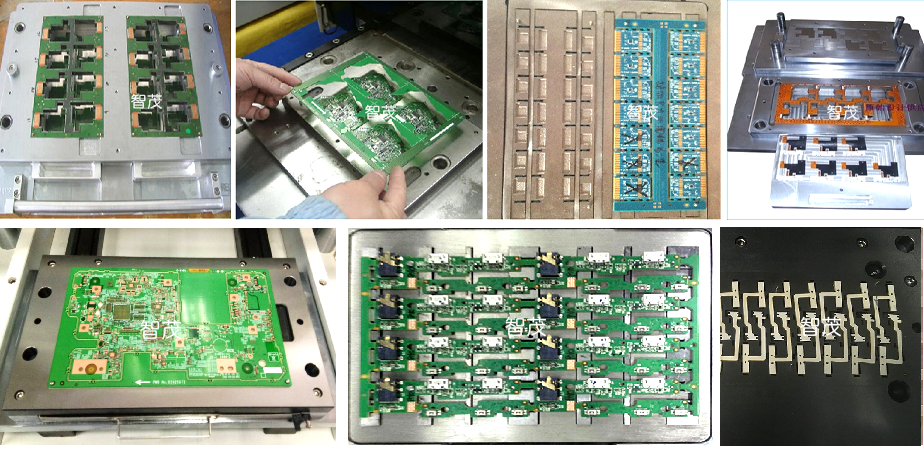

Router Depaneling Machine Series: The core product line utilizes a proprietary high-precision motion control system, achieving cutting accuracy of ±0.05mm and repeatability of ±0.01mm. The 2023-launched GAM386 model features patented bottom-cutting technology, specifically designed for depaneling ultra-thin boards (thickness < 0.4mm) and boards with high-density components, effectively solving issues like warping and component damage common with traditional methods.

Laser Depaneling Machine Series: Provides contactless cutting solutions for flexible circuit boards (FPCBs) and precision components. Seprays’ ZAM series employs UV laser technology with a minimum spot diameter of 15μm, enabling truly stress-free cutting—ideal for high-end applications like wearables and medical implant devices.

Automated Integration Solutions: A key strength is providing complete production line solutions, including auto loaders, fully automatic depaneling machines, unloaders/sorters, and intelligent AGV transport systems. These enable a complete unmanned workflow from “board feeding -> cutting -> sorting -> stacking,” significantly boosting production efficiency.

Industry-Leading Technological Innovation

Seprays invests over 8% of its annual revenue into R&D, maintains a professional R&D team of over 60 engineers, and holds 47 patents in PCB depaneling. Key technological advantages include:

Cutting Precision Control: The proprietary “Real-time Vibration Compensation System” automatically detects and compensates for micro-vibrations during operation, ensuring long-term stability. This system maintains precision deviation within 0.02mm even after 24 hours of continuous operation.

Depaneling Stress Management: The “Multi-parameter Adaptive Cutting System” monitors cutting resistance, spindle load, and material characteristics in real-time, dynamically adjusting parameters to reduce depaneling stress to less than 60% of the industry average.

Smart Integration: Seprays equipment fully supports MES system connectivity, offering rich data interfaces for advanced functions like equipment status monitoring, production data tracing, and preventive maintenance alerts.

Proven Seprays Applications Across Industries

Consumer Electronics

A leading international smartphone manufacturer used the Seprays GAM386 router to depanel mainboards for its latest model. This increased the depaneling yield from 92.7% to 99.9%, saving the company approximately $500,000 annually. The machine’s high-speed cutting capability (up to 300mm/s) also increased line efficiency by 35%.

Automotive Electronics

A European automotive electronics supplier integrated a Seprays laser depaneling machine into its brake control module line to meet the industry’s strict reliability standards. The stress-free cutting ensured long-term PCB reliability, passing 1000-hour high-temperature/high-humidity tests and 50g mechanical shock tests. The machine’s sealed design also effectively contained cutting dust, meeting cleanroom requirements.

Medical Devices

A medical device manufacturer uses Seprays machines to depanel circuit boards for pacemakers. The ultra-high precision cutting (±0.015mm) and fully enclosed, dust-free environment meet the extreme reliability and cleanliness demands of medical electronics. The machine’s batch traceability function also aids compliance with stringent medical industry regulations.

Industrial Control

An industrial automation company implemented a complete Seprays automated depaneling line, transforming a process that required 3 operators into a fully automated operation. This reduced labor costs by 70% and improved the production cycle time from 45 seconds to 28 seconds per panel.

Four Key Reasons Global Buyers Choose Seprays

End-to-End Technical Support: Seprays provides comprehensive support from process evaluation and equipment selection to installation and commissioning. Its experienced application engineering team delivers customized depaneling solutions based on specific production needs.

Reliable After-Sales Network: Seprays commits to 24-hour remote technical support and 48-hour on-site response (for key industrial cities in China). Its global service system ensures customer equipment maintains optimal performance.

Cost-Effectiveness: Compared to European counterparts, Seprays equipment offers comparable or superior performance at typically 30-40% lower cost. Modular design also reduces long-term maintenance costs, with key component replacement times 40% faster than the industry average.

Continuous Upgrade Path: Seprays equipment features an open architecture design supporting future functional upgrades. The company regularly releases software updates and hardware upgrade kits, helping extend the technological lifecycle and service life of customer assets.

Procurement Guide: How to Select the Right PCB Depaneling Machine

Define Production Requirements: Clearly identify needs including PCB type, thickness, material, output volume, and integration requirements with existing production equipment.

Evaluate Technical Fit: Select the most suitable depaneling technology based on PCB characteristics. Router-based machines are often best for rigid boards and complex shapes, while laser technology may be preferable for flexible boards and sensitive components.

Consider Automation Strategy: Assess current and future automation needs. Seprays’ scalable solutions allow for phased upgrades as production capacity grows, protecting the initial investment.

Verify Supplier Credentials: Evaluate the supplier’s technical expertise, industry experience, and service capabilities. Visiting the supplier’s facilities and existing customer sites provides valuable reference.

Calculate Total Cost of Ownership (TCO): Look beyond the purchase price to consider installation, training, maintenance, consumables, and upgrade costs. Seprays provides TCO analysis tools to help customers fully evaluate ROI.

Looking Ahead

With the rapid development of 5G, IoT, and AI technologies, PCB design will continue toward higher density and more complex architectures. Seprays is already investing in R&D for next-generation depaneling solutions to address these trends.

The company is developing an “Intelligent Adaptive Depaneling System” that will incorporate AI-powered vision inspection and machine learning algorithms to auto-optimize cutting parameters and identify defects in real-time. This system is expected to improve depaneling quality significantly while reducing dependency on highly skilled operators.

For three decades, Seprays has focused exclusively on innovating and applying PCB depaneling technology, providing reliable and efficient solutions to global electronics manufacturers. As both Chinese manufacturing and the global electronics industry evolve, Seprays remains committed to being a trusted partner, helping customers worldwide overcome manufacturing challenges and enhance their competitive edge.