Seprays GAM380AT: Vision-Based Automated PCB Depaneling Solution

The Seprays GAM380AT is a vision-based fully automatic PCB router machine designed to meet automated PCB separation needs. This equipment perfectly integrates advanced industrial vision recognition technology with user-friendly operation, delivering high cutting efficiency and simplified visual-assisted programming. It eliminates the need for custom jigs, achieving cost reduction and efficiency improvement. Widely applicable for panelized PCBs in aerospace, communication electronics, semiconductors, medical electronics, automotive electronics, and more.

Four Key Features and Advantages

1. High Efficiency

Utilizes a German-imported spindle with Z-axis hanging components made from integrally cast aluminum, ensuring stable performance while maintaining efficiency. Capacity increased by 30% compared to previous models.

2. High Precision

Features automatic calibration function and high-pixel CCD camera with 15x magnification for improved teaching accuracy, ensuring cutting precision. Supports MARK point setting and full panel scanning.

3. No Visible Dust

Equipped with a 6P high-efficiency dust collector with strong suction to avoid cutting dust contamination. Includes negative pressure detection to remind users to clean the filter bag.

4. No Custom Jigs Required

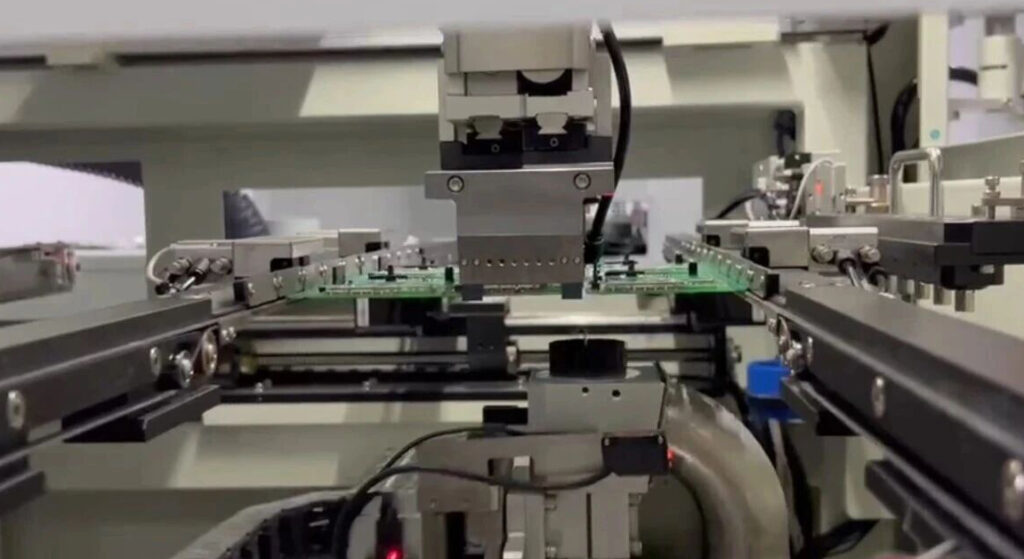

Eliminates the need for custom jigs by clamping the PCBA from the bottom during cutting, saving jig costs and enabling rapid line changeover.

Jig-Free Rapid Line Change Design

The GAM380AT effortlessly handles complex cutting tasks including straight lines, L-shapes, U-shapes, circles, and arcs. Suitable for high-precision products in automotive electronics, medical, military, and other industries. Rapid line changeover requires no separation jigs, saving jig manufacturing costs. Different fixtures can be selected according to PCB cutting requirements.

01. German-Imported Spindle

High-precision spindle with maximum speed of 80,000 rpm/min, featuring milling cutter life management, maintenance alerts, and spindle speed setting management.

02. Precision Depaneling Structure

Z-axis equipped with high-definition CCD module combined with dust collection function. Uses high-speed ESD automatic tool change spindle that actively discharges static electricity generated during the separation process, reducing PCBA damage caused by electrostatic discharge.

03. Two Dust Collection Methods

Optional upper or lower dust collection methods, allowing easy customer switching and adaptation to more products.

Services and Commitments

01. Custom Solution Services

Customize depaneling machine specifications and partial functions according to requirements.

02. Training Services

Comprehensive training system for machine safe operation and application.

03. Rapid Prototyping Services

Supports multiple board materials and cutting prototyping services.

The GAM380AT not only improves production efficiency but is also the optimal choice for enterprises moving toward intelligent manufacturing future!

Seprays Automated Depaneling Machine Brand Commitment

- ✓ Global service network (9 domestic cities + 31 countries/regions overseas, rapid response)

- ✓ 32 years of deep expertise in depaneling machines, hundreds of patents, self-built large modern factory

- ✓ Over 3,000 renowned enterprises have chosen Seprays for long-term cooperation

- ✓ Main products: PCB router machines, laser depaneling machines, saw blade V-cut scorers, punch depaneling machines, etc.

- ✓ Automated solutions including loading/unloading before/after depaneling, tray stacking, and AGV transportation

Welcome to leave a message for a favorable quotation!