1. Introduction: Cutting Challenges in Small-Batch Production

Hardware startups face small-volume, multi-variety PCB depaneling needs. Traditional manual/V-CUT methods cause three critical pain points:

- Stress damage: Hand-breaking generates >500μm stress (IPC-A-610 verified), causing 40% micro-cracks

- Dust contamination: Cutting debris reduces BGA reliability, lowering yields by 15-20%

- Efficiency bottlenecks: Complex boards require 30min/panel, delaying product cycles

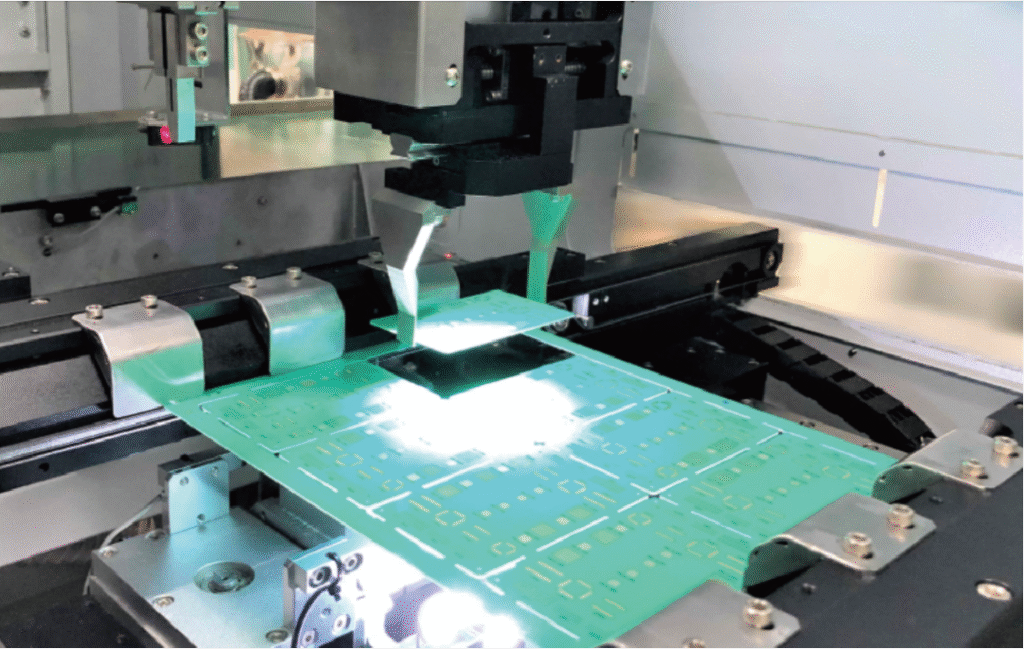

PCB router machines (also called PCB depaneling machines) provide the critical solution: ±0.02mm optical positioning, sealed dust extraction, and irregular board compatibility.

2. Core Selection Criteria for PCB Depaneling Machines

▎ Cutting Accuracy

- Safety threshold: ≤±0.05mm (prevents 0402 component damage)

- Seprays solution: GAM300 series with 12MP CCD achieves ±0.01mm repeatability

▎ Spindle Performance

- Speed range: 60,000-100,000 RPM (ceramic bearing life ≥3,000 hrs)

- Essential feature: ESD protection (<0.1kV discharge)

▎ Application Matching Guide

| Board Type | Recommended Machine | Seprays Model |

|---|---|---|

| Irregular/Multi-hole boards | Vision-based curve cutter | GAM320A |

| Small rectangular boards | Guillotine cutter | HK-200 (40% cost reduction) |

| Flexible PCBs/FPCs | Dual-platform system | GAM336AT |

▎ Automation Level

- Offline (Seprays GAM300): 0.8m² footprint, <5min changeover (ideal for <10 board types)

- Inline (GAM336AT): SMT line integration, 450 UPH output

3. Cost-Efficiency Evaluation Framework

| Cost Factor | Traditional Solutions | Seprays Router System |

|---|---|---|

| Equipment investment | $8,000-$15,000 | $6,200+ (HK-300 series) |

| Monthly tooling cost | $150 | $80 (60% longer tungsten tool life) |

| Hidden costs | 3-5% scrap rate | <0.1% (patented stress control) |

Efficiency benchmarks: ≥100mm/s cutting speed, ≤10min changeover (Quick-Change Fixture System)

4. Startup Selection Strategy

- Lightweight entry: HK-300 benchtop ($6,200, 0.6m² footprint)

- Future expansion: RS-232/ETH interface for robotic integration

- Service assurance: Local support in 9 Chinese cities (sub-24hr response)

5. Seprays Cost-Optimized Solutions

Flagship product: GAM300 Vision Router

- Precision: ±0.01mm alignment, 0.2mm edge clearance

- Cost control: Modular design reduces maintenance by 30%

- Case study: Berlin IoT startup achieved 3× faster depaneling, 82%→99.6% yield

Competitive Advantages

- ✅ 26,000m² production facility (2,000 units/year)

- ✅ Free sample testing (48-hour report)

- ✅ CE/UL certified, 110V/220V compatible

> > Get Custom Solution: https://pcbroutermachine.com/ < <

6. FAQ: Critical Concerns Addressed

How does depaneling stress affect PCBs?

Stress >300μm cracks ceramic capacitors. Seprays machines reduce stress to <50μm (just 1% of manual breaking) via dynamic torque control.

Do startups need inline depaneling machines?

For monthly volume <5,000 panels, choose offline models (GAM300). Seprays provides modular upgrades to inline systems later.

7. Conclusion: Strategic Investment for Growth

Core selection logic for startups:

Precision (±0.05mm) > Application fit > Automation readiness

As a nationally certified specialized SME, Seprays has served 3,500+ global clients over 30 years. From $6,200 entry-level to fully automated solutions, we empower startups to control production quality with minimal investment.