Product Details

ZM30-D Multi-Blade Multi-Component Panel Splitter

One-Time Full LED Board Cutting – Enhances production efficiency and reduces labor costs. Supports custom non-standard configurations, enabling automatic feeding and plate placement post-cutting.

Key Features:

1、High Efficiency: Saves significant labor costs with a daily output exceeding 100,000 pieces.

2、Seamless Automation: Integrates with feeding equipment for end-to-end automated production.

3、Safety Design: Transparent cover + blade housing for dual-layer operator protection.

4、Data Tracking: Monitors and outputs start-up time and production capacity statistics.

5、Precision Adjustment:

Upper/lower blade spacing adjustable to ±0.1mm accuracy.

Compatible with PCB thicknesses of 0.6–3.5mm.

6、Standard 8mm blade width (customizable for LED light strips under 8mm).

Industry-Specific Design:

Optimized for glass tube process production in lighting, meeting strict anti-deformation requirements.

Also suitable for aluminum-plastic tube LED light strips and strip-type PCB boards.

Application:

PCB boards with V-grooves, thickness 0.2 to 3.0 mm, such as aluminum boards, copper boards, FR4 boards, fiberglass, T5T8 light strips, light boards, etc.

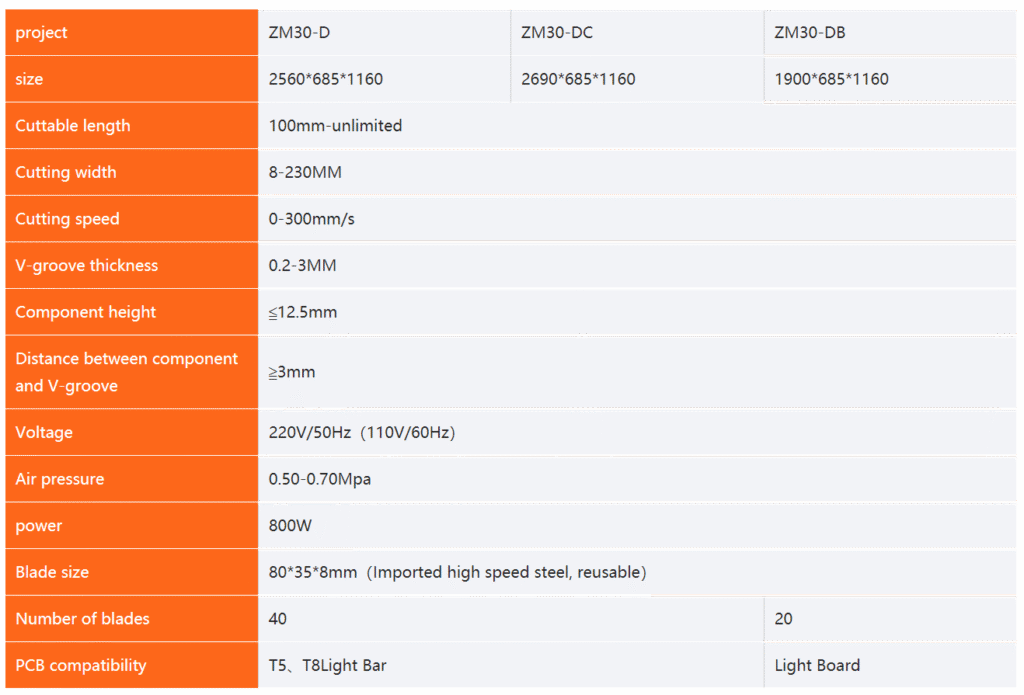

Parameter

What services do you provide?

What services do you provide?

We provide one-stop automated PCB depaneling solutions: laser, routing, punching and V-CUT.

Can your machines handle different thicknesses of PCBs?

Yes, our machines are designed to handle various PCB thicknesses. We can provide customization and options to ensure smooth processing of both rigid and flex boards.

What type of training do you provide for your machines?

We provide comprehensive on-site training, covering machine operation, maintenance, and troubleshooting. We also offer ongoing technical support via phone and email.

What after-sales services can you provide?

●Exclusive service:

We will give users feedback within 10 minutes on any problems they encounter when using the device and establish a 1V1 exclusive after-sales service group for users.

●Remote service:

Provide users with a 7*24H hotline based on feedback on fault information, analyze, locate, and solve the fault through remote telephone support,remote login, and other methods.

●On-site service:

Arrive at the work site within 8 hours and solve the problem within 1 working day. 2-4 days of training on equipment safety operation and application.Any breach of contract will be handled by the contract provisions.

●Service locations:

We have sales and service support in 31 countries and regions overseas, responding to customers’ current and future needs as soon as possible.

●Benchmark service:

Follow-up call after each visit; video tutorials + telephone guidance on parts replacement and equipment maintenance; free follow-up month in December every year. We continue to collect user suggestions, continuously update and iterate the software, improve user production quality and efficiency, and provide lifelong maintenance.