In the high-volume, precision-driven world of electronics manufacturing, Surface Mount Technology (SMT) lines represent the core of PCB assembly. While significant focus is rightly placed on optimizing printing, placement, and reflow processes, the depaneling stage—separating individual boards from a manufactured panel—remains a critical yet sometimes overlooked determinant of overall line efficiency, yield, and throughput. Integrating an automated depaneling machine directly into the SMT line flow is a strategic move that can address key bottlenecks and enhance overall operational performance.

The Traditional Bottleneck: Manual and Semi-Automatic Depaneling

Historically, depaneling was often performed manually using break-out tabs or with simple, stand-alone routers. This approach creates several inefficiencies:

-

Throughput Limitation: Manual separation is slow, creating a natural bottleneck that prevents the SMT line from achieving its full output potential.

-

Inconsistency and Stress: Hand-breaking or using basic tools imposes mechanical and torsional stress on the PCB, potentially causing micro-cracks in components, solder joints, or the board substrate itself, leading to latent field failures.

-

Contamination and Safety: Generating dust and debris, manual methods can contaminate boards and pose a safety and cleanliness challenge in a controlled production environment.

-

Labor Dependency: The process is labor-intensive, variable in quality, and scales poorly with increasing production volumes.

Automated Depaneling: A Integrated Solution

Modern automated depaneling machines eliminate these issues by providing a precise, reliable, and fast method for board separation that seamlessly integrates into the end of the SMT line. The primary technologies employed are:

-

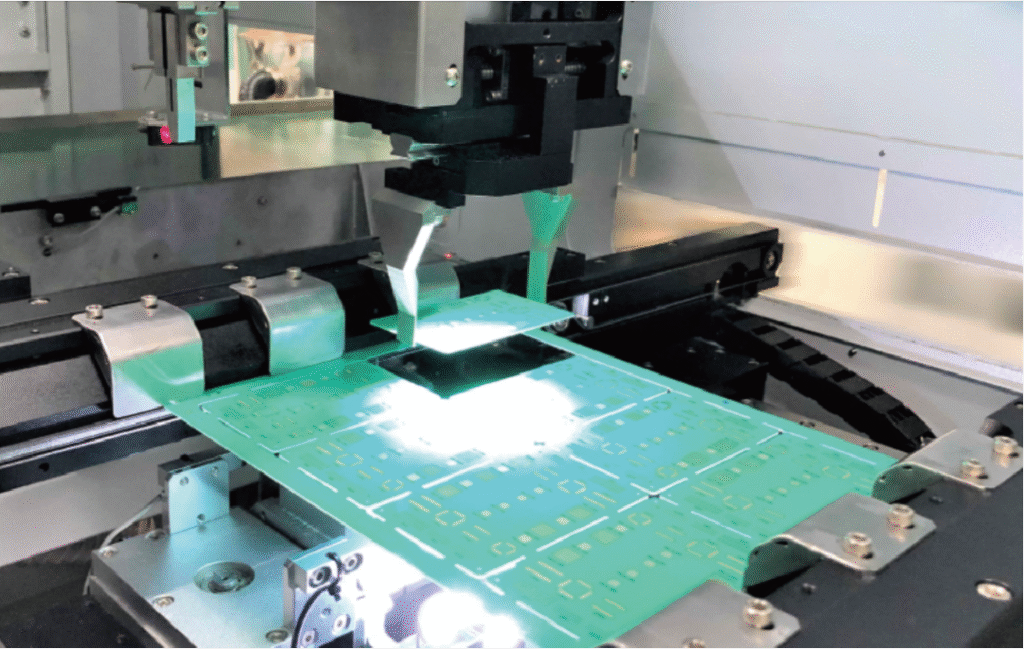

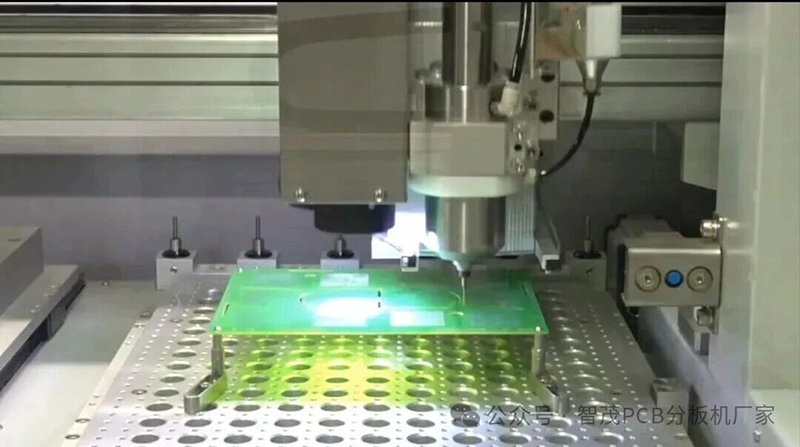

Router/铣刀 Depaneling: Utilizes a high-speed spindle and precision routing bit to cut along programmed paths. This method is highly versatile, handling complex board shapes, tight tolerances, and sensitive components near the board edge with minimal stress and no thermal effect.

-

Laser Depaneling: Employs a high-power laser (typically UV) to ablate material along the cut line. This is a completely contactless and force-free process, ideal for ultra-fragile boards, rigid-flex PCBs, and applications requiring the absolute highest precision with zero mechanical stress or dust.

[Saw/V-Scoring Depaneling: Uses a specialized saw blade to separate panels that have been pre-scored (V-cut). It offers a very fast, clean, and straight cut for panels designed with standard V-grooves.]Saw/V-Scoring Depaneling: Uses a specialized saw blade to separate panels that have been pre-scored (V-cut). It offers a very fast, clean, and straight cut for panels designed with standard V-grooves.

-

Punch Depaneling: Best suited for high-volume, identical simple-shaped boards, using a hydraulic or mechanical punch and die set for instantaneous separation of the entire array.

Impact on SMT Line Efficiency

Integrating an automated depaneling machine yields measurable improvements across several key metrics:

-

Increased Throughput: Automated machines cycle in seconds, matching or exceeding the pace of modern SMT lines, thereby removing the depaneling bottleneck and unlocking full line capacity.

-

Enhanced Yield and Quality: Precision cutting eliminates mechanical stress, dramatically reducing board damage, cracked components, and compromised solder joints. This leads to higher final test yields and improved long-term product reliability.

-

Process Consistency and Data Integration: Automated machines operate with digital programs, ensuring every panel is separated identically. They can be integrated into factory networks for traceability and process control, supporting Industry 4.0 initiatives.

-

Reduced Operational Costs: While requiring capital investment, these machines reduce labor costs, minimize scrap and rework due to damage, and lower costs associated with field failures.

-

Enabled Automation: Automated depaneling is the essential link for a fully automated SMT line. Machines can be equipped with automatic loaders, unloaders, stackers, and connected via conveyors or AGVs to the preceding SMT and subsequent testing/packaging stages, creating a continuous, lights-out production flow.

Integration Considerations

Successful integration requires careful planning:

-

Technology Selection: The choice between router, laser, saw, or punch depends on PCB design (tab routing, V-score), component proximity, board material, and required throughput.

-

In-Line Placement: The machine should be positioned post-reflow and pre-test/inspection. Its conveyor system must align with the SMT line height and speed.

-

Handling Automation: To maximize gains, pairing the depaneler with automated handling solutions for loading panels and offloading singulated boards is crucial.

Conclusion

In the pursuit of leaner, faster, and more reliable SMT manufacturing, the depaneling process demands the same level of engineering focus as earlier assembly stages. Implementing an advanced, automated depaneling machine is not merely an upgrade to a single station; it is a systemic improvement that enhances the efficiency, quality, and automation potential of the entire SMT line. By transitioning from a manual, variable process to a precise, integrated, and data-capable one, manufacturers can achieve significant gains in productivity and product integrity.

About Seprays

Seprays is a leading provider of advanced PCB depaneling solutions, dedicated to enhancing manufacturing efficiency and quality for the global electronics industry. With over 32 years of deep specialization in depaneling technology, Seprays supports a vast customer base of more than 3,000 renowned enterprises worldwide.

The company’s expertise is built on a foundation of over 100 patented technologies and a large, modern manufacturing facility. Seprays offers a comprehensive range of depaneling systems, including precision Router Depanelers, stress-free Laser Depanelers, high-speed Saw/V-Scoring Depanelers, and Punch Depanelers. Furthermore, Seprays provides complete automation integration, supplying front-end and back-end loading/unloading, sorting, and AGV material handling solutions for seamless SMT line integration.

Backed by a responsive global service network spanning 9 major Chinese cities and 31 countries/regions overseas, Seprays delivers reliable technical support wherever its customers operate.