How to Upgrade Offline PCB Depaneling Machines to Smart Inline Systems: Robotic Automation Guide

With rapid industrial automation, traditional offline depaneling machines struggle to meet demands for high-speed, precision-driven electronics manufacturing. Upgrading to inline robotic systems is now critical for maintaining competitive advantage. Here’s a proven implementation framework:

I. Core Upgrade Architecture

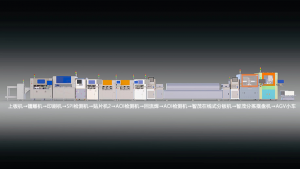

Inline Transformation

Retrofit existing offline PCB depaneling machines (e.g., Zimo models) for direct integration with SMT lines, eliminating manual transfers.

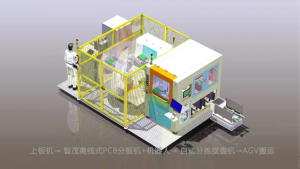

Robotic Material Handling

Deploy 6-axis collaborative robots (cobots) to automate PCB loading/unloading between conveyors and depaneling machines while maintaining ±0.02mm placement accuracy with ESD-safe grippers.

End-to-End Automation

Synchronize AGVs for WIP transport, automated sorting palletizers, and MES-driven process control to create seamless workflow integration.

II. Operational Benefits

⚡ 30-50% Faster Cycle Times

Achieve continuous 24/7 production with 50+ boards/minute throughput through automated processing.

? 70% Labor Cost Reduction

Slash operational costs while saving 40% on capital expenditures compared to new inline equipment purchases.

? Medical-Grade Precision

Maintain ≤0.05mm cutting tolerances for 01005 components and rigid-flex PCBs, meeting IPC-A-610 Class 3 standards.

? Plug-and-Play Flexibility

Enable rapid changeovers under 15 minutes for mixed-volume production runs.

? Real-Time Traceability

Industry 4.0 MES integration provides OEE dashboards, predictive maintenance alerts, and component-level traceability.

III. Industry Applications

• Consumer Electronics

Smartphone/tablet mainboard depaneling with ESD protection for high-volume production.

• Automotive Electronics

ADAS module processing compliant with IPC-A-610 Class 3 quality standards.

• Medical Devices

Hermetic sealing-critical PCB separation in ISO 14644-1 Class 5 environments.

• Aerospace & Defense

RF/microwave board handling with MIL-STD-883 compliant ESD protocols.

• Telecom Infrastructure

5G mmWave antenna array processing requiring sub-millimeter accuracy.

Case Study: Automotive Manufacturing Success

A German automotive supplier implemented this solution, reducing depaneling defects by 82% while achieving ROI in 9.2 months. Post-upgrade, their line efficiency (OEE) increased from 63% to 89% with full ESD S20.20 compliance.