Why is Choosing the Right PCB Depaneling Machine Crucial?

In the electronics manufacturing industry, PCB depaneling is a critical step in the post-SMT process. Selecting an unsuitable depaneling machine can lead to a series of hidden costs and quality risks: mechanical stress causing solder joint cracks and component damage; cutting burrs affecting electrical performance and assembly; low efficiency dragging down overall line output; frequent equipment failures driving up maintenance costs… These pain points not only impact product yield but can also damage a company’s reputation.

Conversely, a high-quality, well-matched PCB depaneling machine can significantly improve the quality consistency of PCB assembly, enable efficient and stable depaneling operations, reduce reliance on manual labor, and lay the foundation for moving towards automated and intelligent production. It is not merely a piece of equipment but a key enabler for process assurance, efficiency, and cost control.

This article aims to provide you with a systematic, objective purchasing guide. We will move beyond simple parameter lists and sales pitches, starting from real needs to guide you step-by-step in clarifying your thinking and making the investment decision that best suits your actual production and future development.

Step 1: Define Your Requirements – The Foundation of All Choices

Before evaluating any equipment, clear self-assessment is the first step. Examine your current production situation and goals from the following four dimensions:

1. PCB Board Characteristics

Board Material Type: Common FR-4, aluminum substrate with high heat dissipation requirements, flexible boards (FPC) prone to deformation, or complex rigid-flex boards?

Board Thickness and Size: What is the thickness range for depaneling? What are the maximum and minimum panel sizes?

Panel Design and Connection Method: V-CUT or breakaway tabs (mouse bites)? Parameters like V-groove depth, remaining thickness, or tab spacing and quantity directly affect the depaneling method and tool selection.

Component Layout: Are there tall components like connectors or capacitors near the board edge? What is the overall component density? This relates to the complexity of the cutting path and the need for visual positioning.

2. Capacity and Efficiency Requirements

Production Volume: What is the daily or monthly quantity of PCBs requiring depaneling?

Cycle Time Requirements: Does the production line have specific takt time requirements for depaneling a single board? This determines the minimum speed requirement for the equipment.

3. Precision and Quality Requirements

Cutting Precision: What are the tolerance requirements for the outline dimensions after depaneling?

Quality Threshold: What are the minimum acceptable standards for cutting stress, board edge burrs, and dust generated during the process? Some high-reliability products (e.g., automotive electronics) have extremely strict requirements for stress control.

Process Control: Is SPC data from the cutting process needed for quality traceability and analysis?

4. Production Environment and Future Planning

Site Conditions: What is the available installation space? Are power, air supply, and dust extraction connections readily available?

Automation Integration: Is it currently a standalone workstation, or are there plans to integrate it into a fully automated SMT line in the future (requiring connectivity features)?

Future Outlook: Will the product line iterate towards thinner, higher density, or more diverse materials in the next 1-3 years? The equipment should possess a certain degree of adaptability.

Step 2: Understand Mainstream PCB Depaneling Machine Types and Their Applications

Understanding the principles and characteristics of different depaneling technologies is key to accurately matching needs with machine types.

1. Blade Depaneling Machine

Principle & Characteristics: Uses a straight or circular blade to score and snap boards apart along V-grooves. Low cost, simple operation, suitable for straight-line V-cut panels.

Best Applications: Simple, low-volume, budget-conscious depaneling of FR-4 boards with straight lines.

Limitations: Generates relatively higher stress, may produce burrs, not suitable for curved or irregular shapes.

Brief Case: For simple, low-mix production, it remains a cost-effective entry point. For example, Seprays offers reliable blade depaneling solutions for basic needs.

2. Router Depaneling Machine (PCB Router Machine)

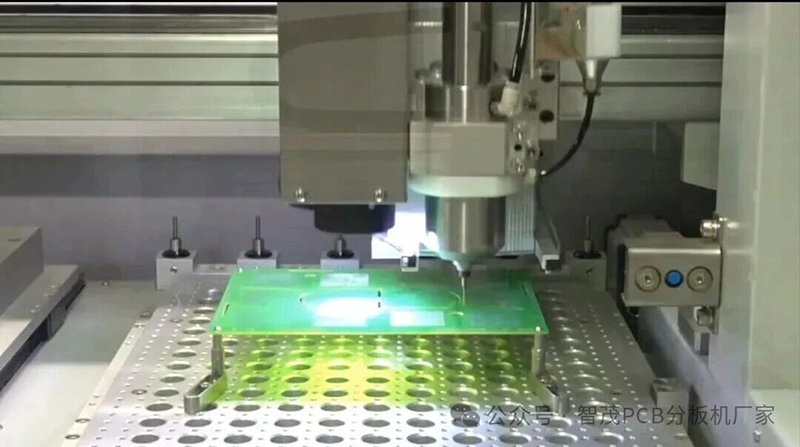

Principle & Characteristics: Uses a high-speed spindle and routing bit to cut, controlled by a CNC system for programmable paths. This is the current mainstream choice for high-precision, low-stress depaneling. Highly flexible, it can handle any shape (straight lines, curves, irregular outlines) and is suitable for both V-cut and tab-routed panels.

Categories: From entry-level manual models (cost-effective), to fully-automatic vision-based models (using CCD cameras for precise positioning, ideal for boards with high components requiring avoidance), to inline fully-automatic models (can be directly integrated into SMT lines for automated flow).

Best Applications: High-precision, high-complexity PCBs like smartphone motherboards, automotive electronics, medical devices; tab-routed panels; rigid-flex boards; and any application with strict requirements for low cutting stress.

Case Integration: As a core equipment in modern, efficient SMT lines, high-end vision-based router depaneling machines have become the upgrade choice for many electronics manufacturers due to their exceptional precision and flexibility. For instance, Seprays’ [GAM-340AT Inline Automatic PCB Router Machine] integrates a high-precision vision system and efficient dust extraction, designed specifically for the high standards of automated production lines.

3. Laser Depaneling Machine

Principle & Characteristics: Uses a high-energy laser beam for non-contact melting/vaporization cutting. Entirely free of mechanical stress, produces smooth, burr-free edges with extremely high precision.

Best Applications: Ultra-thin PCBs, Flexible Printed Circuits (FPC), ceramic substrates, semiconductor packaging, and cutting of special materials and highly sensitive components.

Limitations: Highest equipment investment cost; potential for slight charring with some materials (like FR-4); cutting speed is generally slower compared to router machines.

Case Integration: For the growing demand for FPC and precision module cutting, laser depaneling offers an irreplaceable solution. Seprays’ [ZAM330-AT Inline Laser Depaneling Machine] combines automatic loading/unloading, laser cutting, and palletizing, providing ultimate quality for cutting advanced flexible and rigid boards.

Step 3: Five Core Dimensions for Evaluating a PCB Depaneling Machine

After determining the machine type direction, evaluate specific equipment and suppliers based on the following five in-depth dimensions.

1. Cutting Precision and Quality

Key Metrics: Focus on the equipment’s repetition positioning accuracy and cutting path following accuracy, which directly determine depaneling consistency.

Core Support: Precision stems from a robust mechanical structure (e.g., high-rigidity gantry), high-precision motion system (linear motors are superior to ball screws), and a high-performance spindle (high RPM, low runout).

Quality Control: Excellent equipment should offer a complete cutting quality solution, including controlling burrs through process parameter optimization and specialized tooling, solving dust with an efficient multi-stage filtration extraction system, and optionally integrating stress monitoring sensors to quantify and control cutting stress.

2. Equipment Stability and Durability

Foundation Determines Lifespan: Examine if the frame uses monolithic cast iron or stress-relieved steel construction, which determines long-term stability. The brands of key components (like spindle, linear guides, servo motors) are the cornerstone of reliability.

Craftsmanship Reflects Strength: The quality of assembly and calibration determines the equipment’s ability to maintain precision under long-term, high-load operation. This is key to differentiating brand heritage.

3. Production Efficiency and Automation Level

Loading/Unloading Method: Manual, semi-automatic, or fully automatic (with conveyor or robotic arm). The choice should match the production line’s automation level and labor cost considerations.

Positioning Technology: Full vision positioning (CCD) has become standard for high-end models. Evaluate its recognition accuracy, speed, and adaptability to different panels and reflective components.

Operational Ease: Is the software intuitive and user-friendly? Does it support direct import of Gerber or DXF files to generate cutting paths? The programming and setup time for product changeovers is critical for efficiency in high-mix, low-volume production.

4. Safety and Usability

Safety Protection: Must be equipped with full enclosure guards, safety light curtains, emergency stop buttons, etc., complying with international safety standards.

Human-Machine Interface (HMI): Is the touchscreen interface logically clear? Is daily maintenance (e.g., tool change, lens cleaning) designed to be simple and convenient?

5. Supplier’s Professional Service and Support (Key area to highlight Seprays’ advantages)

Pre-sales Expertise: Can the supplier deeply understand your process pain points and provide professional solution evaluation? Can they offer free sample testing to demonstrate actual cutting results?

After-sales Support System: Is installation and training comprehensive? What is the response speed for after-sales service (e.g., our commitment to 24-hour rapid response)? Is the spare parts inventory sufficient? Is technical support localized and professional? We firmly believe that “free sample testing” and “customized, in-depth training” are the best commitments to help customers mitigate risks and maximize equipment value.

Step 4: Avoid Common Purchasing Pitfalls

Pitfall 1: Comparing Only Price, Ignoring Total Cost of Ownership (TCO). A low purchase price may mean higher failure rates, shorter lifespan, lower efficiency, and staggering maintenance costs.

Pitfall 2: Seeking a “Universal Machine,” Resulting in Wasted Investment. Using a high-end laser machine to cut simple FR-4 straight lines is overkill.

Pitfall 3: Neglecting the Future, Leading to Quick Obsolescence. Failing to consider potential product iterations can render the equipment unsuitable soon after deployment.

Pitfall 4: Blindly Trusting Paper Specs, Lacking Physical Verification. Impressive specifications don’t equal excellent real-world performance.

Our Advice to You: “Seeing is believing, testing is proving.” Before making a final decision, insist on conducting a live or video demo test using your actual PCB samples. This is the most reliable way to verify a machine’s capabilities.

Step 5: Summary and Actionable Recommendations

1. Review the Decision Path: First, look inward to clarify your needs. Then, look outward to match the suitable depaneling technology type. Finally, conduct a deep evaluation of the equipment’s core dimensions and the supplier’s overall strength.

2. Final Checklist:

[1] Have my PCB material, thickness, connection method, and component layout been clearly defined?

[2] Have my capacity, precision, and automation needs been quantified?

[3] Is the chosen machine type the most suitable for my primary products?

[4] Has the equipment’s precision, stability, efficiency, and safety been verified?

[5] Has the supplier provided satisfactory sample test reports and comprehensive service commitments?

3. Our Sincere Invitation:

> Choosing the right PCB depaneling machine is a significant investment impacting quality, efficiency, and competitiveness. As a professional manufacturer with years of expertise in the PCB depaneling field, [Seprays] not only provides a full spectrum of depaneling solutions from blade and router to laser machines but is also committed to being your reliable process partner.

>

> We possess proprietary visual positioning systems and vibration-damping structure patents, and have served numerous globally renowned electronics manufacturers. We believe the best recommendation comes from actual cutting results. We invite you to provide your PCB samples for a free cutting test and solution evaluation, letting the facts help you make the wisest, most confident decision.

>

> Contact us today to obtain your customized depaneling optimization plan.