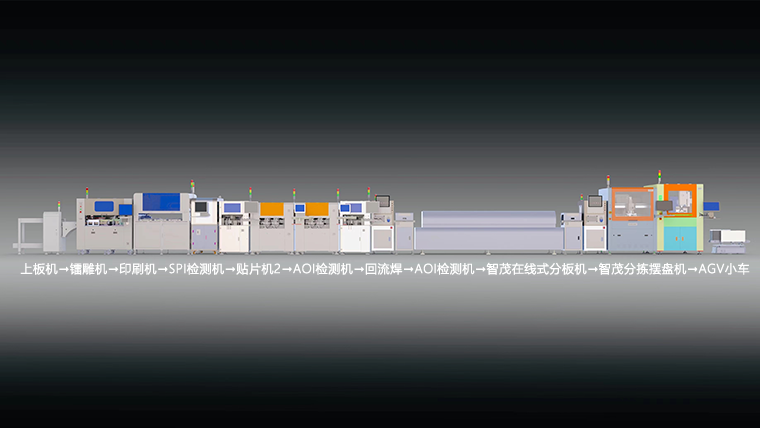

High-End SMT Line Solutions: Critical Role of Depaneling & Sorting Machines

In industries demanding extreme reliability like automotive electronics and medical devices, automated SMT lines enable precision assembly. Seprays’s inline depaneling machines and sorting palletizers ensure optimal production efficiency.

Target Industries

Telecom equipment, smartphones/PCs/TVs, 3C consumer electronics, instrumentation, automotive electronics, medical devices, LED lighting – where product reliability is mission-critical.

4 Core Features of Premium SMT Lines

High Efficiency: 30% faster production cycles via automation and AI-driven optimization

Pinpoint Accuracy: ±0.01mm placement heads with AOI vision ensuring component consistency

Production Flexibility: 10-minute changeovers for high-mix low-volume (HMLV) manufacturing

Uncompromised Reliability: Advanced control systems with real-time monitoring achieving >99.5% yield

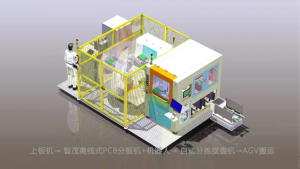

SEPRAYS Equipment Capabilities

Inline Depaneling Machine: Precision separation of soldered PCBs via V-cut/tab routing (±0.05mm accuracy, 30+ boards/min)

Automated Sorting Palletizer: IPC-compliant PCB sorting and tray loading, tripling throughput while eliminating manual errors