Router depaneling technology has become the standard configuration for high-end electronics manufacturing. According to a 2024 report by the International Electronics Industry Association, companies adopting high-precision router depaneling machines have seen their PCB assembly yield rates increase by an average of 2.3 percentage points, with the equipment investment payback period shortened to 14-18 months.

Top 10 FAQs on Router Depaneling Machines

1. What are the main advantages of router depaneling compared to other methods?

Router depaneling cuts using high-speed rotating carbide tools. Its advantages are threefold: extremely low cutting stress (typically <10 MPa), avoiding micro-cracks; high cutting accuracy (up to ±0.02mm), suitable for high-density boards; and excellent edge quality, eliminating the need for secondary processing. Compared to the stress concentration issues of punch depaneling and the heat-affected zone problems of laser depaneling, router depaneling shows clear advantages for rigid and multi-layer boards.

2. What are the key accuracy metrics for the equipment, and how are they verified?

Core accuracy metrics include positioning accuracy (±0.01mm), repeatability (±0.005mm), and cutting perpendicularity (≤0.015mm). Verification involves cutting a standard test board and measuring critical dimensions, using a micrometer to check deviations between the cut profile and the design drawing. Seprays equipment undergoes a 72-hour continuous accuracy test using a laser interferometer before leaving the factory, with a test report provided.

3. What types of PCBs can the equipment typically handle?

Modern router depaneling machines can process boards from 0.2mm ultra-thin to 4.0mm thick, with a common maximum processing size of 600×600mm. They effectively handle materials like FR-4, aluminum substrates, ceramic substrates, and rigid-flex boards. For PCBs with bottom-side components like BGAs or QFNs, intelligent height detection automatically avoids components for safe cutting.

4. What is the typical lifespan of the router bit, and what is the replacement cost?

The lifespan of a standard carbide router bit under normal use is 800,000 to 1.2 million cuts, depending on PCB material and thickness. Seprays employs a patented tool wear monitoring system that provides real-time replacement alerts. Each bit costs approximately $80-$150; compared to the value of a high-end PCB, the tooling cost constitutes less than 0.3%.

5. How does the equipment adapt to different cutting path shapes?

By importing design files via CAD/CAM software, the machine automatically generates the cutting path. Advanced machines like the Seprays series support multiple path optimization algorithms. For irregular shapes, curves, or multi-board panels, they automatically calculate the optimal cutting sequence and feed rate, maximizing efficiency while reducing heat buildup.

6. How long does a production changeover take?

While traditional machines require over 30 minutes for setup, Seprays machines reduce changeover time to under 5 minutes using a recipe management system. Operators simply recall a stored program, and the machine automatically completes tool calibration, vacuum zone adjustment, and vision system alignment.

7. How is the dust generated by the equipment managed?

Effective dust management is crucial for cut quality and equipment longevity. Seprays machines use a four-stage filtration system: primary filter for large particles, cyclone separator for medium particles, HEPA filter for fine dust (99.97% efficiency on particles ≥0.3μm), and activated carbon for odor absorption, maintaining a clean workspace.

8. How does the equipment integrate with existing production lines?

Modern router depaneling machines support multiple communication protocols (SECS/GEM, Modbus TCP/IP, Profinet) for seamless MES integration. Seprays provides standardized interfaces with proven integration cases in large EMS factories like Foxconn and Flex, with an average integration time of only 2-3 working days.

9. What routine maintenance is required, and at what frequency?

Basic maintenance includes daily dust collection unit cleaning, weekly linear guideway lubrication, and monthly vacuum system seal checks. The intelligent maintenance system in Seprays equipment provides early warnings and guides operators step-by-step. Annual professional maintenance by factory engineers is recommended to ensure long-term accuracy.

10. What is the typical Return on Investment (ROI) period?

Depending on the industry, the ROI period ranges from 12 to 24 months. For high-volume consumer electronics, payback is typically achieved in 12-15 months. For automotive and medical electronics with lower volumes but higher quality demands, the reduction in quality costs ensures payback within 18-24 months. Seprays offers professional ROI analysis tools to help accurately forecast investment benefits.

Recommended Seprays Router Depaneling Machines

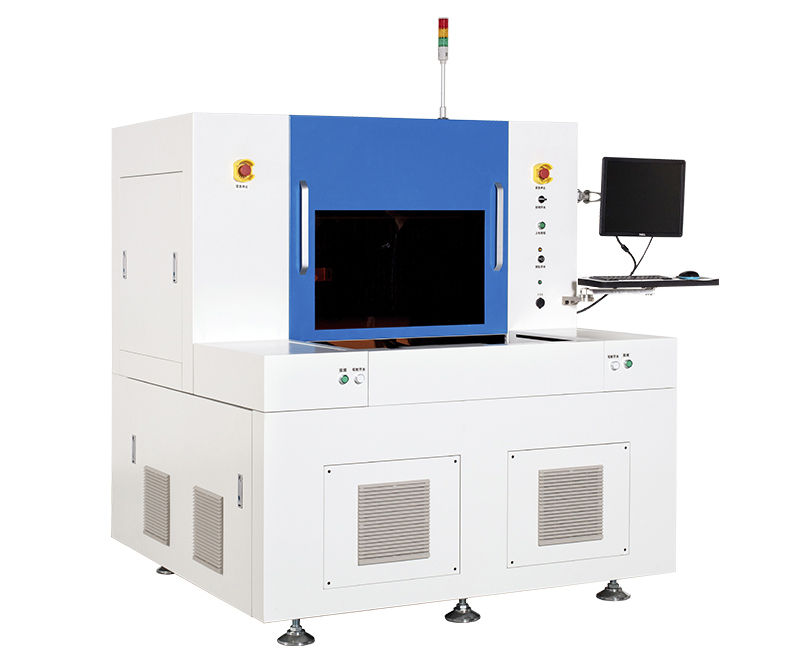

GAM386 Series: High-Speed, High-Precision All-Rounder

The GAM386 series is Seprays’ flagship product for medium-to-high volume general applications, with over 800 units sold globally.

Key Specifications:

Max. Processing Size: 610mm × 610mm

Positioning Accuracy: ±0.007mm

Max. Speed: 400mm/s

Spindle Speed: 30,000-80,000 rpm (adjustable)

Tool Diameter: 0.8mm-3.175mm

Repeatability: ±0.003mm

Technical Highlights:

The GAM386 features a dual-servo drive system and temperature-compensated linear guides for stability at high speeds. Its patented “Adaptive Feed Control” automatically adjusts cutting parameters based on PCB laminate material and copper distribution, reducing depaneling stress on typical V-CUT boards by 40%.

It comes standard with a 12MP high-definition vision system, recognizing 0.2mm fiducial marks with a positioning time of just 0.8 seconds. The optional dual-table configuration enables parallel loading and cutting, theoretically increasing throughput by up to 85%.

Ideal Applications:

The GAM386 is particularly suited for batch production in consumer electronics, network communication equipment, and industrial control modules. It excels in applications like smartphone mainboards and router core boards. A case study with Foxconn showed a 99.94% yield rate for iPhone mainboard depaneling, with a single machine capacity reaching 450,000 panels per month.

ZAM330 Series: Precision & Flexibility Specialist

The ZAM330 series is designed for low-volume, high-mix production environments, specializing in complex irregular boards and precision modules.

Key Specifications:

Max. Processing Size: 330mm × 250mm

Positioning Accuracy: ±0.005mm

Max. Speed: 300mm/s

Spindle Speed: Up to 100,000 rpm

Min. Tool Diameter: 0.4mm

Repeatability: ±0.002mm

Differentiating Advantages:

The ZAM330’s standout features are rapid changeover and precision machining. Its 16-tool automatic changer and intelligent tool management system allow processing different PCB thicknesses and shapes without manual tool changes. For irregularly shaped rigid-flex boards common in medical devices, its 3D contour following function maintains cutting depth consistency with an error of less than ±0.015mm.

The fully enclosed design maintains a 10Pa positive pressure inside to prevent external contamination. An integrated particulate sensor monitors cleanness in real-time, meeting the high-reliability requirements of medical and automotive electronics.

Ideal Applications:

The ZAM330 is ideal for precision depaneling in automotive ECUs, medical implant devices, aerospace electronics, and high-end wearables. In a European luxury automotive brand’s ECU production line, the ZAM330 achieved perfect depaneling of 0.3mm thick ceramic substrates, sustaining a yield rate above 99.97%.

The maintenance log from that Shenzhen electronics company shows that the Seprays router has operated continuously for 27 months with precision loss not exceeding 15% of its nominal value, requiring only two preventive maintenance sessions. This exemplifies why customers in over 40 countries choose Seprays—acquiring not just a machine, but a time-tested precision manufacturing solution.

Whether it’s the GAM386 for efficient, stable production or the ZAM330 for precision and flexibility, Seprays offers more than just the competitive pricing of “Made in China.” It provides deep process understanding and reliable technological execution honed over three decades in PCB depaneling. When making your procurement decision, we recommend comparing your specific production needs against these professional insights and product features to find the optimal solution for your line.