Product Details

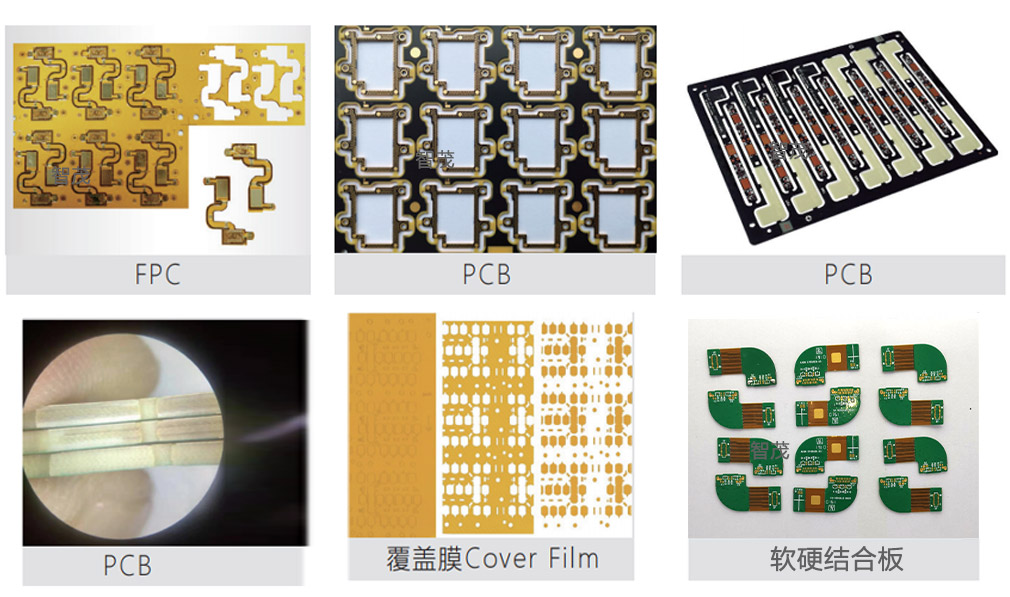

Application

Product Features

1. User Interface

• Simplifies depaneling parameter settings (milling cutters/jigs).

• Clearly displays processing efficiency and milling cutter usage data.

• Features a historical log window for easy operation record review.

• Includes milling cutter life management, maintenance alerts, and spindle RPM configuration.

2. Four-Tier Access Control

• Supports password-protected accounts with customizable permission levels for different roles.

• Optional fingerprint recognition login module for enhanced security management.

3. CCD Vision Auto-Calibration System

• Equipped with a high-speed CCD vision auto-calibration system.

• Simulates cutting paths to assist programming, ensuring path accuracy.

• Enhances path editing efficiency with whole-board scanning and offline programming.

4. Offline Programming & Whole-Board Scanning

• Edit cutting programs offline and import directly into the machine to maximize utilization rate.

• Intuitive, user-friendly interface with automatic cutting path recognition.

• Edit scanned PCB layouts to modify cutting paths rapidly and improve programming efficiency.

• Selectable cutting line colors for easy identification on different PCB substrates.

5. Laser Height Sensing

• Optional laser height module verifies PCBA placement in jigs, preventing cutting deviations or damage caused by misaligned boards or debris.

• Enables rapid line changeover by recalling stored programs and eliminating jig setup errors.

Parameter

-

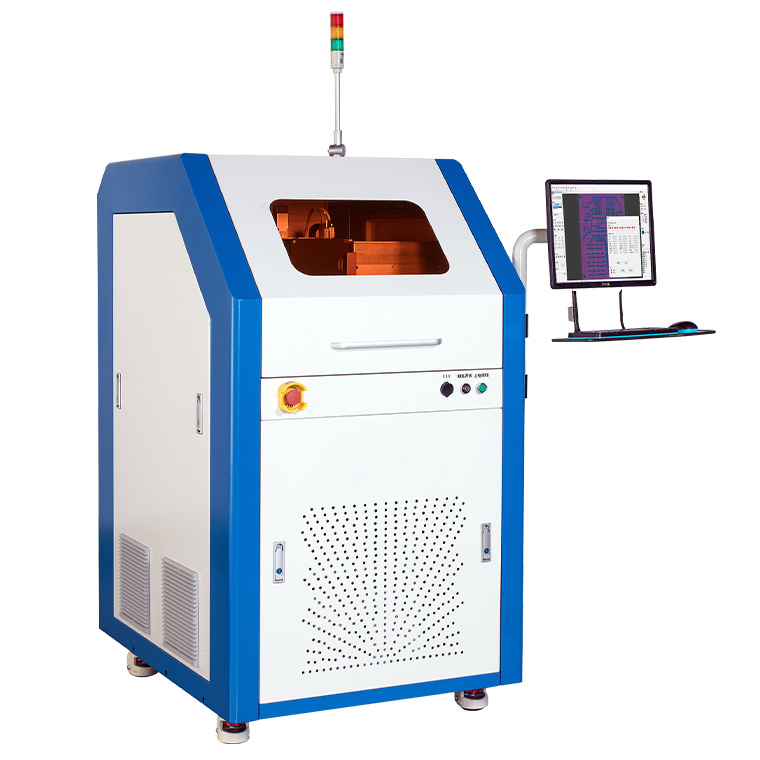

ModelZAM320

-

LaserGreen and UV; Picosecond and Nanosecond Options

-

Laser Wavelength355nm/532nm

-

Overall Accuracy±20μm

-

Repetition Accuracy±2μm

-

Processing HeadGalvo scanner,Scanlab

-

Vision AlignmentCCD,1,600,000 pixels

-

Max. working area350mm*300mm

-

Working table height900±50mm

-

Working tableGranite Table, Linear Motor

-

SecuritySafety Light Curtain, Automatic Door

-

Data Processing SoftwareCircuitCAM 7 Standard

-

Driver SoftwareDreamCreaTor 3

-

Dimensions (Height × Width × Depth)1,624mm*917mm*1,207mm

-

Weight700kg

-

Power380VAC/ 50Hz, 4.5kW

What services do you provide?

What services do you provide?

We provide one-stop automated PCB depaneling solutions: laser, routing, punching and V-CUT.

Can your machines handle different thicknesses of PCBs?

Yes, our machines are designed to handle various PCB thicknesses. We can provide customization and options to ensure smooth processing of both rigid and flex boards.

What type of training do you provide for your machines?

We provide comprehensive on-site training, covering machine operation, maintenance, and troubleshooting. We also offer ongoing technical support via phone and email.

What after-sales services can you provide?

●Exclusive service:

We will give users feedback within 10 minutes on any problems they encounter when using the device and establish a 1V1 exclusive after-sales service group for users.

●Remote service:

Provide users with a 7*24H hotline based on feedback on fault information, analyze, locate, and solve the fault through remote telephone support,remote login, and other methods.

●On-site service:

Arrive at the work site within 8 hours and solve the problem within 1 working day. 2-4 days of training on equipment safety operation and application.Any breach of contract will be handled by the contract provisions.

●Service locations:

We have sales and service support in 31 countries and regions overseas, responding to customers’ current and future needs as soon as possible.

●Benchmark service:

Follow-up call after each visit; video tutorials + telephone guidance on parts replacement and equipment maintenance; free follow-up month in December every year. We continue to collect user suggestions, continuously update and iterate the software, improve user production quality and efficiency, and provide lifelong maintenance.