In the fast-growing global electronic manufacturing industry, PCB depaneling has become a critical process directly impacting production efficiency, product quality, and overall operational costs. According to industry reports, the global PCB depaneling machine market reached \(289 million in 2024 and is projected to grow to \)450 million by 2031, with a compound annual growth rate (CAGR) of 6.6%. Among various depaneling technologies, punch-type depaneling machines have emerged as a preferred choice for B2B manufacturers seeking speed, precision, and reliability—especially for high-volume production scenarios. Below, we explore the core advantages of punch-type depaneling machines and how Seprays’ specialized solutions elevate these benefits for global clients.

1. Unmatched Production Efficiency for High-Volume Manufacturing

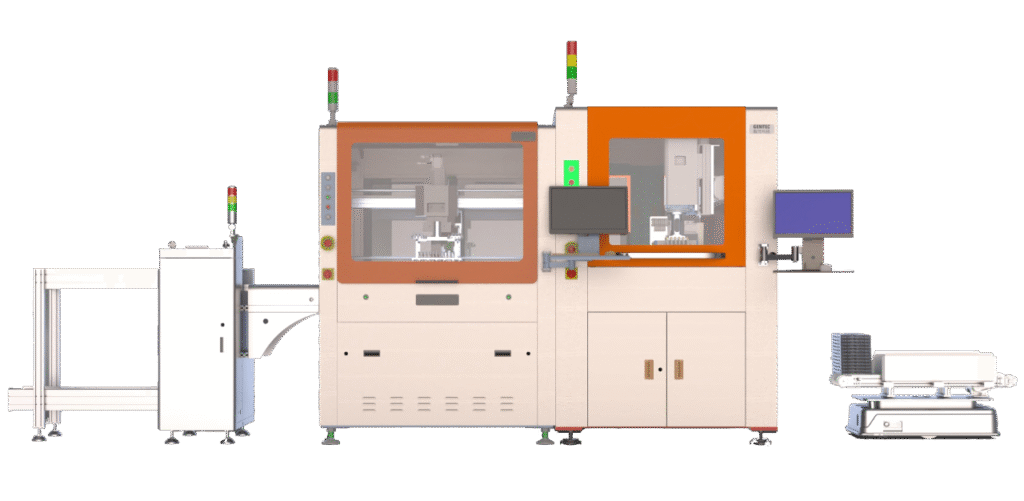

Punch-type depaneling machines stand out for their exceptional speed, making them ideal for mass production lines. Unlike laser or milling depanelers that require sequential cutting, punch-type machines use a stamping mechanism to separate PCBs in one swift motion. Specifically, Seprays’ punch-type depaneling machines can process 6 to 8 panel boards per minute, significantly outperforming traditional manual or semi-automatic methods. For B2B clients in consumer electronics, automotive electronics, and LED manufacturing—where throughput directly impacts profitability—this efficiency translates to reduced lead times, higher output, and improved economies of scale.

2. Precise and Consistent Cutting Quality

Accuracy is non-negotiable in PCB manufacturing, and punch-type depaneling machines deliver consistent results even for complex board designs. Seprays’ punch-type depanelers feature a rigid, cast-aluminum frame and precision-engineered dies that ensure cutting accuracy within tight tolerances. The machines are designed to handle V-groove PCBs, LED aluminum substrates, and copper substrates, with the ability to cut boards where components are as close as 0.2mm to the V-groove edge—eliminating the risk of component damage caused by misalignment or uneven force. This consistency is critical for industries like automotive and medical electronics, where product reliability is regulated and non-negotiable.

3. Low Stress to Protect Sensitive Components

One of the most significant advantages of punch-type depaneling is its low-stress cutting process. Unlike sawing or milling, which can generate vibration and thermal stress, the punch mechanism applies uniform force in a single stroke, resulting in stress levels below 400 microstrain. This gentle cutting method protects sensitive components such as capacitors, resistors, and microchips from damage, reducing scrap rates and rework costs. For B2B clients producing high-value PCBs for industrial controls, IoT devices, or medical equipment, this low-stress advantage directly enhances product yield and long-term performance.

4. Durability and Low Maintenance Costs

Punch-type depaneling machines are built for heavy-duty use, with robust components that withstand continuous operation in demanding factory environments. Seprays’ machines are paired with high-quality consumables—such as the CW-1.2mm-SS304 砂轮 cutting blades (with a service life of 50,000–60,000 cuts)—to ensure long-term reliability. The simple mechanical structure of punch-type machines also means fewer moving parts, reducing the need for frequent maintenance and minimizing downtime. Additionally, Seprays offers global support, including 48-hour rapid delivery of replacement parts from its warehouses in the US, Germany, and Singapore, further lowering total cost of ownership (TCO) for international B2B clients.

5. Versatility Across Materials and Applications

Punch-type depaneling machines are highly adaptable to different PCB types and materials, making them a versatile investment for B2B manufacturers with diverse product lines. Seprays’ punch-type solutions can handle unlimited-length PCBs, V-groove boards, aluminum substrates, and copper substrates—catering to industries ranging from consumer electronics (smartphones, tablets) to automotive (infotainment systems, sensors) and LED lighting. Whether you’re producing small, delicate PCBs or large, rigid panels, the machines can be customized with interchangeable dies to meet specific cutting requirements, eliminating the need for multiple specialized depaneling tools.

Why Choose Seprays’ Punch-Type Depaneling Machines?

At Seprays, we combine decades of expertise in PCB depaneling with a focus on B2B client needs. Our punch-type depaneling machines integrate advanced features such as automatic counting, safety interlocks, and tool-free die replacement—streamlining operations and reducing human error. Complemented by our high-quality consumables and global service network, our solutions ensure consistent performance, minimal downtime, and maximum ROI. To explore our full range of punch-type depaneling machines and find the perfect fit for your production line, visit our product page: https://pcbroutermachine.com/.

Ready to Boost Your PCB Production Efficiency?

Are you looking to reduce cycle times, lower scrap rates, and enhance the reliability of your PCB depaneling process? Seprays’ punch-type depaneling machines are engineered to meet the demands of high-volume, precision-focused B2B manufacturing. For a customized consultation, detailed technical specifications, or a free quote tailored to your production needs, contact our expert team today at jimmy@seprays.com. Let us help you unlock the full potential of punch-type depaneling and stay ahead in the competitive electronic manufacturing landscape.